In today’s world, where climate change and resource depletion are constant hot topics, sustainable engineering has become a crucial field. Our future innovations should create solutions that both meet our needs, and also protect our planet for future generations. As we move ahead, understanding how technology readiness levels (TRLs) fit into the picture can help us innovate responsibly.

NASA originally created TRLs in the 1970s for space exploration technologies, to provide a standardized framework on where a technology stands on its journey from idea to reality. During the 1990s, NASA expanded the TRL scale from seven to nine levels. Following NASA’s lead, various organizations, including the U.S. Department of Defense (DoD and the European Space Agency (ESA), began adopting and adapting the TRL framework for their own needs.

Many industries now use TRLs to evaluate technology maturity and inform funding decisions. Let’s dive into what TRLs are all about, and why they matter..

What are Technology Readiness Levels (TRLs)?

Technology Readiness Levels are a way to measure how mature a technology is throughout its development process. Systematic, metrics-based assessments are done to evaluate how developed a technology is, and the risks involved in its development. These assessments usually span the entire journey of a technology, from its initial invention all the way to its commercialization and widespread use.

Technology Readiness Level (TRL) ratings specifically indicate how close a technology is to being implemented in real-world applications by industries or the public. These ratings help to justify the use of resources such as time, money, materials, skill, and facilities, to turn a technology into a practical solution. Let’s look at a simple example that helps us better understand this concept.

Simple Example: Bread-Making

Imagine you’re preparing to bake bread. You gather all the necessary ingredients. You have everything you need. Yet, if you haven’t mixed them together, your bread is at a very low level of readiness. You have the basic components, but they are not yet functioning as a cohesive unit (Bread).

Only when it’s baked and cooled can you serve it. At this point, the bread signifies a high level of readiness. It is properly set. You can slice it and serve it to your friends or family. Everything will have come together perfectly without any further modifications or adjustments.

Similarly, in technology, a lower TRL means more work is needed before it can be used effectively. A higher TRL indicates that the technology is almost ready for deployment.

Technology Readiness Levels Metrics

TRL rankings and metrics for technology assessment as adapted from NASA and DOD practice;

TRL 0: Unproven Idea

No Analysis or testing performed

TRL 1: Basic Principles observed and reported

Scientific Research translated into applied research and development. The basic principles underlying the concept are identified

TRL 2: Concept Formulated

Practical Application is invented based on general assumptions or preliminary analysis of the underlying principles.

TRL 3: Proof -of-concept

Analytical and experimental studies are performed on a lab scale to confirm analytical predictions.

TRL 4: Lab-Scale demonstration (“low fidelity”)

Basic technological components are integrated to will work together. They are then compared with system goals.

TRL 5: Lab-Scale Demonstration

(“high fidelity”)

Basic technological components are integrated with realistic supporting elements and, tested in a simulated environment. Barriers for targeted performance goals are identified and plans to overcome them formed.

TRL 6: Prototype System designed

The system is integrated with support elements, and model design is created and tested in a simulated or operational environment. Outcomes should be close to system target goals.

TRL 7: Prototype System is demonstrated in an operational environment

The Prototype System is near or at planned operational efficiency, and is applicable in it’s target environment. Results of prototype testing show success.

TRL 8: Actual System Completed

The system is qualified through tests and demonstrations. The Technology assessments meets its operational requirements. Design is fine-tuned.

TRL 9: The actual system successful

Actual system is in its final form under mission conditions. It is also ready for the market.

Continuous reports done on real application performance.

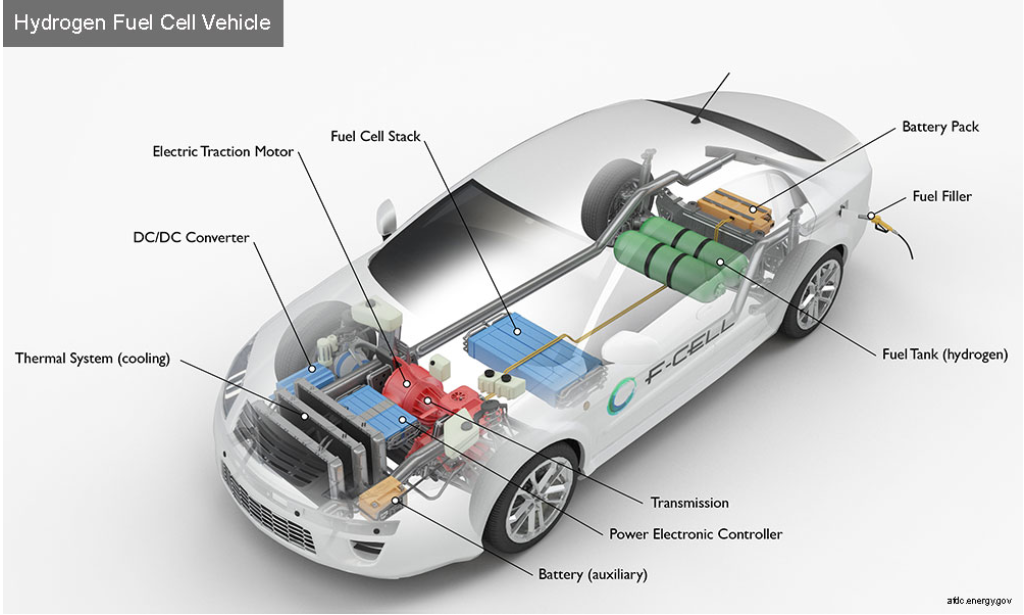

Advanced Example: Hydrogen Fuel Cells Electric Vehicle

In 2012, an Early market TRL Analysis of Hydrogen fuel cells was done by Pacific Northwest National Laboratory for the US Department of Energy Fuel Cell Technologies Program (FCTP). Find the report here

Over the years, significant funding from government and private sectors fueled research and development efforts in Hydrogen fuel cell technology. Real-world pilot projects such as hydrogen-powered trucks and buses, provided valuable data that validated technology performance under operational conditions. This led to significant progress in hydrogen fuel cell technology across various industries.

Finally, hydrogen fuel cells reached TRL 9 when they were fully operational in commercial applications. Notable examples include their use in NASA’s Space Shuttle program and Alstom’s hydrogen-powered train.

The International Energy Agency rated the technology TRL 8-9 in 2023. This came after several commercial orders were purchased in several countries across the transportation sector. Find the report here.

Sources; SFC Energy and US DOE

TRLs showing progression of Hydrogen Fuel Cells

| TRL Level | Description | Innovation & Application |

|---|---|---|

| TRL 1 | Basic Principles Observed and Reported. | Fundamental research on electrolysis and fuel cell chemistry to get conceptual understanding of hydrogen fuel cells. |

| TRL 2 | Concept Identified and potential applications formulated. | Theoretical models and early design concepts are established during initial feasibility studies for hydrogen applications. |

| TRL 3 | Proof-of-concept demonstrated. | Development of prototypes and small scale demonstrations in a controlled environment. |

| TRL 4 | Lab-Scale Demonstrations (“Low Fidelity”) where components are validated in laboratory settings. | Lab tests for individual components such as membranes and catalysts were done to ensure fuel efficiency. |

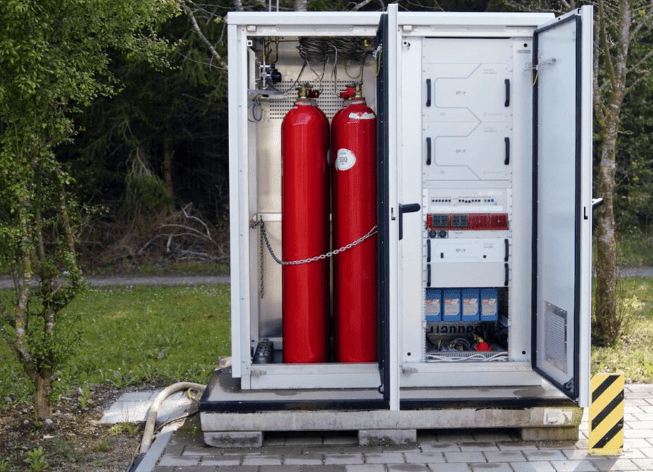

| TRL 5 | Lab-Scale Demonstrations (“High Fidelity”) where system components are validated in relevant environments. | Integration of tested components into functional systems and pilot projects done for stationary power generation. |

| TRL 6 | Prototype System designed and tested in operational environments. | Full-scale prototypes of hydrogen-powered vehicles were designed and tested. |

| TRL 7 | System is completed and qualified. Integrated prototype system demonstrated in operational environments. | Advanced testing done in actual operational settings. Commercial trials were done via public transportation vehicles to prove it could well be well-integrated into the transport system. |

| TRL 8 | Actual System completed and incorporated into commercial design. | Final adjustments ensured commercial viability and reliability. Hydrogen fuel cell electric vehicles (FCEVs) were implemented. Drivetrains for rail were introduced. |

| TRL 9 | Actual System Successful and proven in an operational environment | Full operational deployment in various sectors i.e. -Hydrogen fuel cells powering forklifts (Toyota) -Hydrogen powered trucks (Volvo) – Alstom’s hydrogen-powered Coradia iLint train. |

Please watch this 15 minute video in which Dr. Sean McCarthy (Hyperion Ltd) provides more examples, and examines the ties of TRL assessment to the decision making and choosing partners for a project.

This video was made in the context of the European innovation and technology implementation landscape, but many of those insights are completely transferable all over the world.

Leave a comment